- Industries

- Products

- Store

- Resources

- Contact

NOW

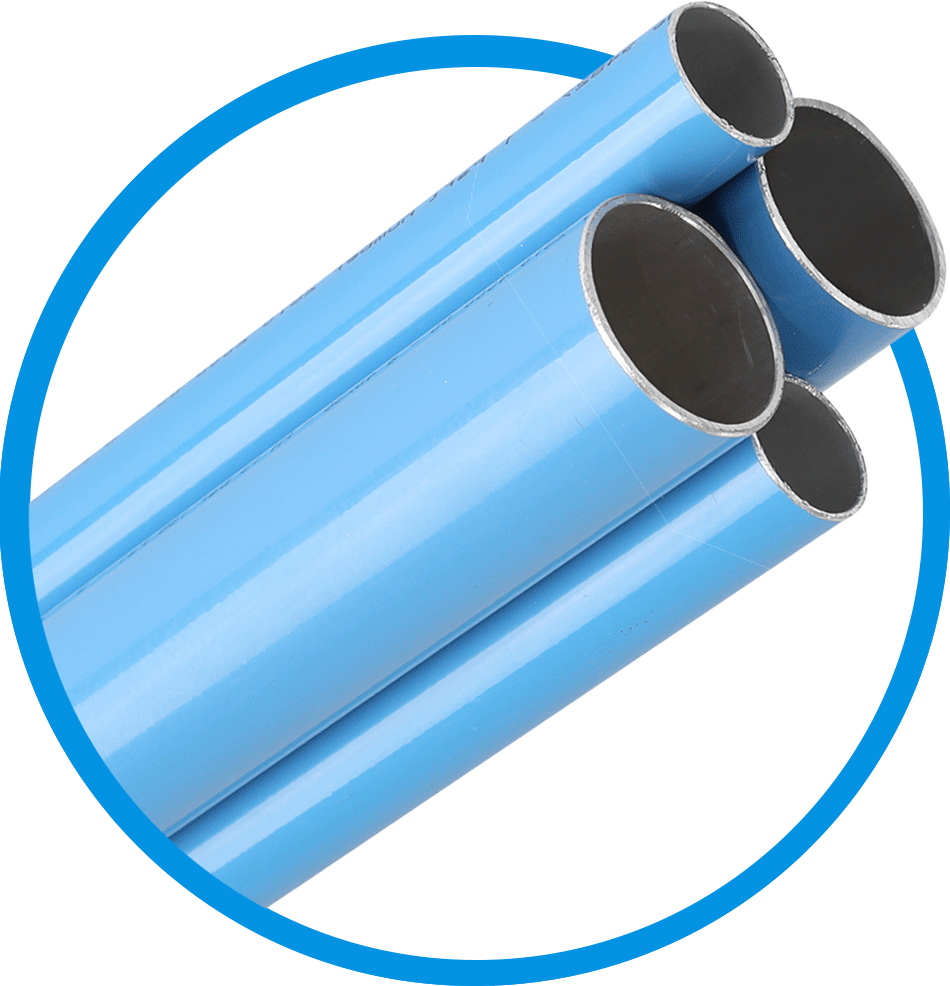

Rigid Blue Aluminum Piping

Made In The Usa

Compressed

Air Products in Action

Tommy Pike, founder of Tommy Pike Customs and star of Custom Carolina outfitted his shop with FastPipe by RapidAir to customize rigs faster and more efficiently.

Paint Society breaks down what you need to achieve smooth, professional paint finishes using airguns powered by FastPipe.

Outfitting your shop with a compressed air system? Pro Tech Machinery provides a step-by-step explanation of the entire FastPipe installation process.

Sizing

FastPipe ComPRESSed Pressure: 232 psi

3/4” FASTPIPE

Outside Diameter: 20mm (.79 in)

1” FASTPIPE

Outside Diameter: 25mm (.98 in)

1-1/2” FASTPIPE

Outside Diameter: 40mm (1.57 in)

2” FASTPIPE

Outside Diameter: 50mm (1.97 in)

3” FASTPIPE

Outside Diameter: 80mm (3.15 in)

4” FASTPIPE

Outside Diameter: 100mm (3.94 in)

6” FASTPIPE

Outside Diameter: 150mm (5.90 in)

Black Pipe

Copper Pipe

Total Material Costs

(PIPING, FITTINGS, ETC.)

INSTALLATION TIME

Total 500ft Compressed Air System Installation Cost

$1,538

36% less than FastPipe

40 Hours

667% more than FastPipe

$5,538

185% more than FastPipe

$2,849

19% more than FastPipe

35 Hours

583% more than FastPipe

$6,449

215% more than FastPipe

$2,397

6 Hours

$2,997

Other Considerations

Material Familiarity + Popularity

Ongoing Maintenance

Modifications

Working Pressure

Overall Cost of Ownership

Worst

Better

Best

Black Pipe

Copper Pipe

Fast Pipe

Total Material Costs (Piping, Fittings, etc.)

$1,538

36% less than FastPipe

$2,849

19% more than FastPipe

$2,397

Installation time

40 Hours

667% more than FastPipe

$2,849

583% more than FastPipe

6 Hours

Total 500ft Compressed Air System Installation Cost

$5,538

185% more than FastPipe

$6,449

215% more than FastPipe

$2,997

Other considerations

Material Familiarity + Popularity

Ongoing Maintenance

Modifications

Working Pressure

Overall Cost of Ownership

Make installation a breeze with RapidAir’s FastPipe aluminum piping for compressed air

FastPipe delivers a superior single source aluminum compressed air piping solution that can be easily installed by one person, in half the time. Lightweight and available in multiple sizes, FastPipe’s long, straight blue air compressor lines are corrosion resistant, can connect to all existing piping systems, and can be mounted on ceilings, inside or outside walls.

When speed matters, choose FastPipe.

RIGID PIPE MADE

IN THE USA

All RapidAir rigid compressed air piping is proudly made in America, which maintains faster shipping at competitive prices, less supply chain disruption and quicker inventory availability.

ALUMINUM PIPES FOR SUPERIOR AIR QUALITY

FastPipe aluminum piping for compressed air are corrosion resistant. No corrosion in the pipe and fittings helps keep air compressor lines clean and free of debris, extending the life of tools. Cleaner air also translates to lower maintenance costs. Offering a professional look, FastPipe’s straight blue piping runs with minimal obstructions, supports multiple air users and powers the operation of heavy-duty tools.

Get it done fast, get it done right with RapidAir FastPipe.

SHOP

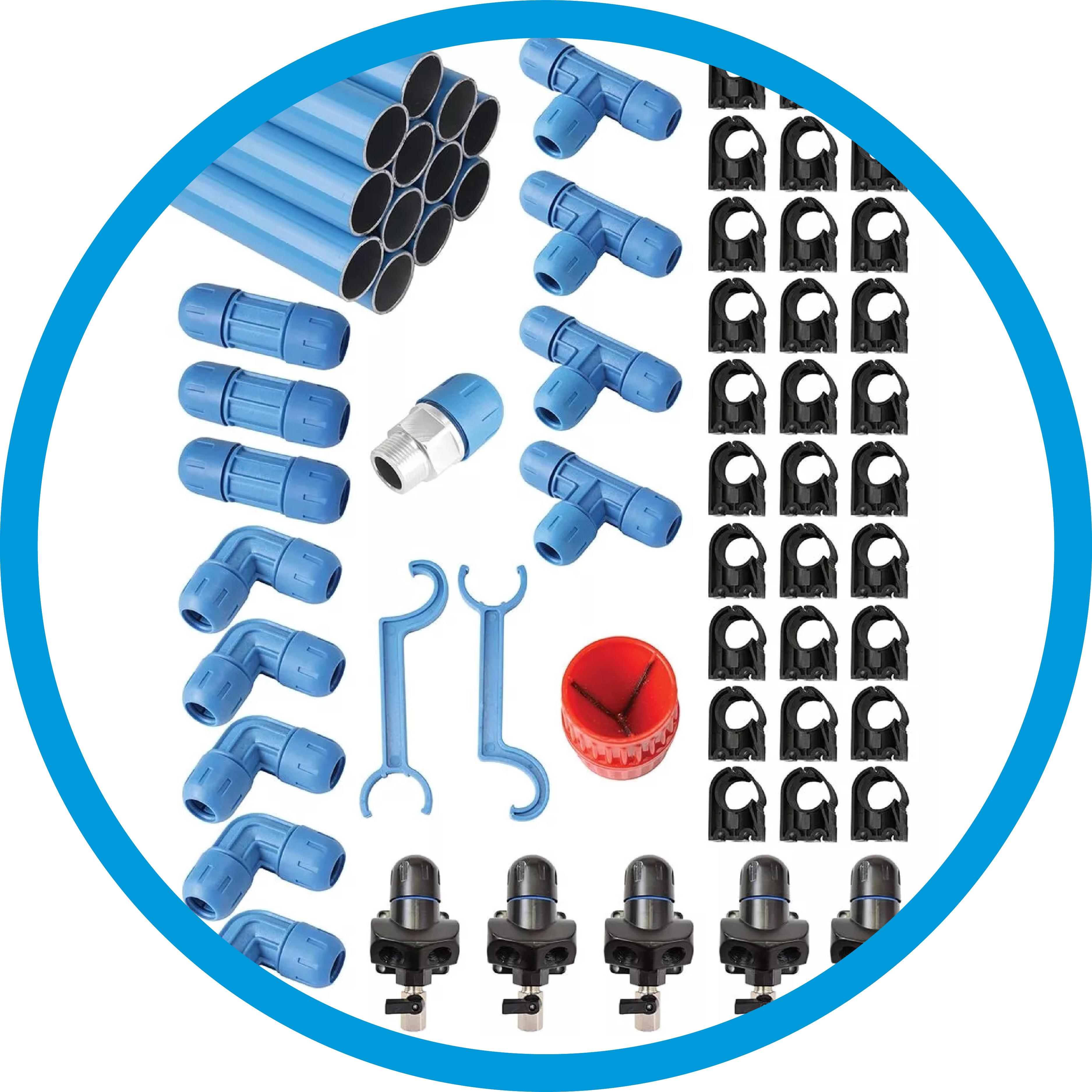

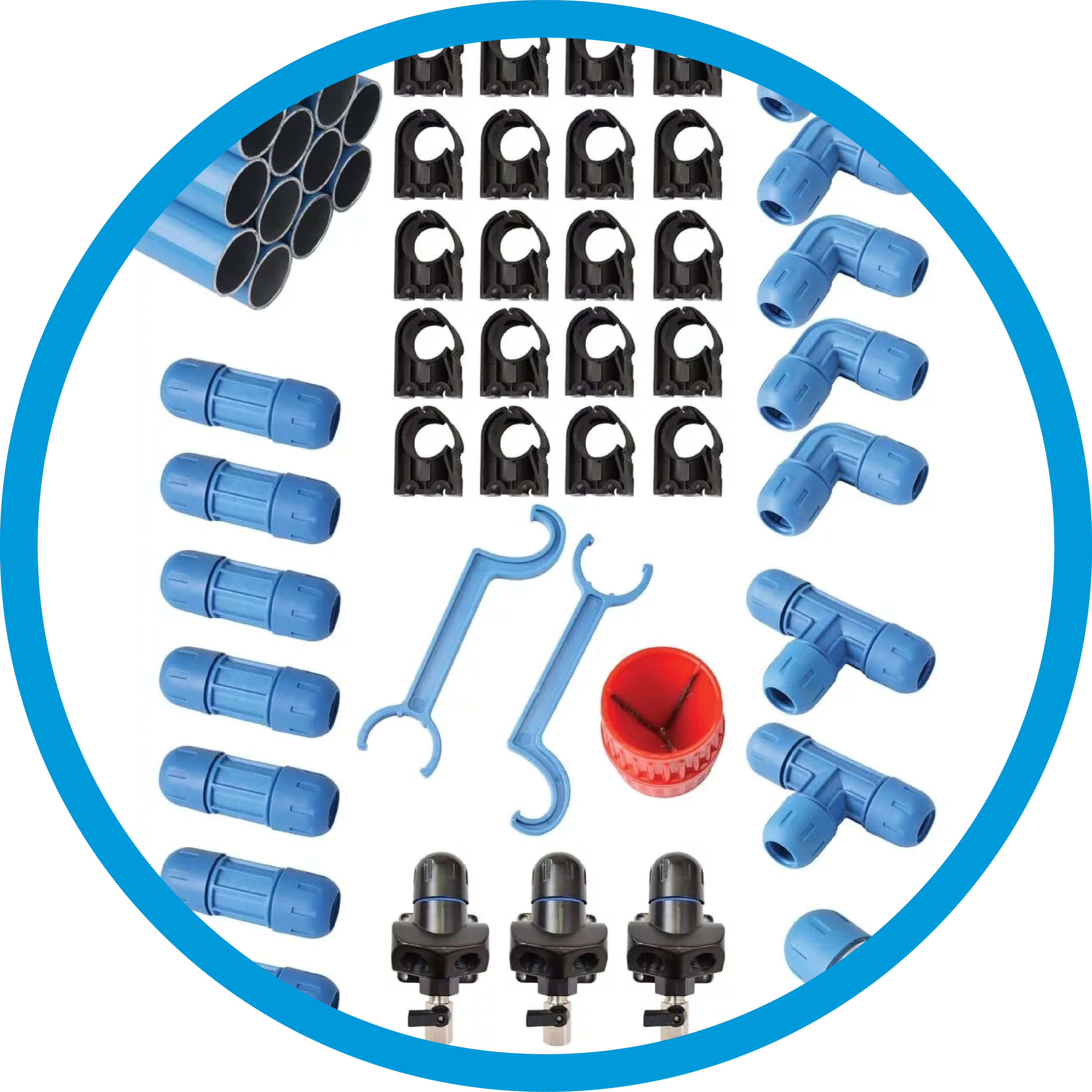

MASTER KITS

Save time, money and hassle with FastPipe’s modular aluminum compressed air piping Master Kits. Available in multiple sizes and lengths, Master Kits have everything you need, bundled in one kit to get the job done right, fast.

Not sure which kit is best for you? Use our "Help Me Decide” tool.

SHOP

FITTINGS

COMPRESSION

Reusable compression fittings are ideal for residential or commercial spaces that need the flexibility to expand/modify their compressed air system.

COMPRESSION

ADVANTAGE

No press tool is required for install; fittings can be disassembled and reused.

Compression fittings are suitable for air, vacuums and inert gases.

Fittings are made with fiberglass reinforced nylon (2” fittings and under) or black aluminum die cast (3” fittings).

PRESS

PRESS

ADVANTAGE

Press tools create easy, permanent, and reliable connections.

When used with FastPipe, press is suitable for non potable water, oils, lubricants, compressed air, vacuum and inert gas applications.

The stainless steel material provides long-term UV sensitivity and remains leak free without readjustments once the fitting is pressed on.

SHOP

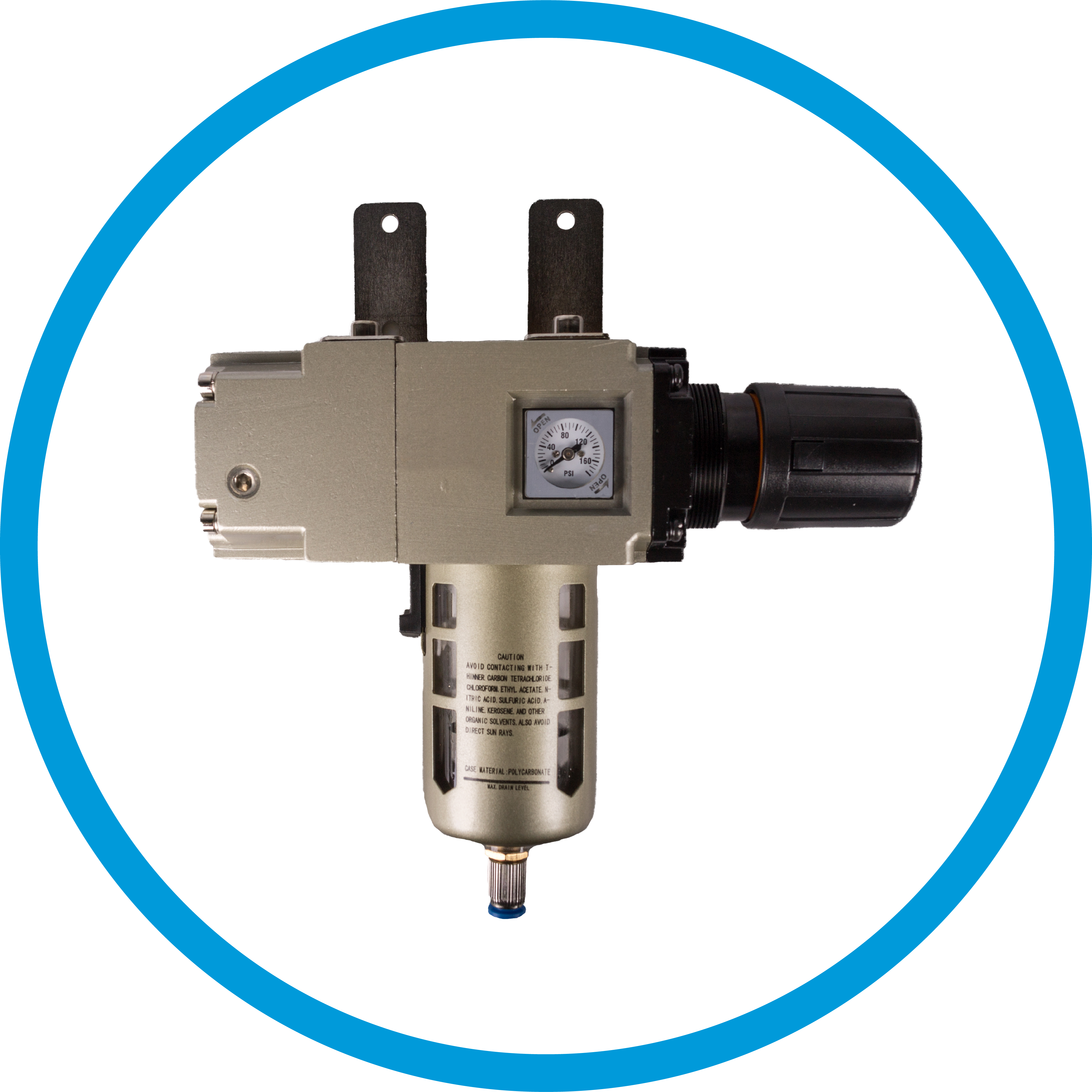

TOOLS & ACCESSORIES

As your single source for complete industrial grade compressed air solutions, RapidAir has everything you need to streamline operations.

FAQs

FOR COMPRESSED AIR SOLUTIONS

A compressed air piping system delivers compressed air from the source (compressor) to the point of use (tools, equipment) while maintaining optimal pressure and air quality. Fastpipe rigid blue air compressor lines delivers a long, straight, corrosion-resistant piping solution with multiple mounting options that can be easily installed by one person, in half the time.

CHECK OUT THE

INDUSTRIES WE SERVE

THE RAPIDAIR

ADVANTAGE

STREAMLINE OPERATIONS:

DIRECT TO CUSTOMERS:

QUALITY AND AVAILABILITY:

SOLUTIONS SUPPORT:

EASY INSTALLATION OPTIONS:

LOW MAINTENANCE & GUARANTEES:

HOW CAN WE HELP?

Need a parts list bid or a gut check to counter a competitor’s estimate? Personable, friendly service is our trademark, and our expert technical support staff is at your service as you take your next steps.

CALL US AT 866-253-2093 OR CONTACT US TODAY.