- Industries

- Products

- Store

- Resources

- Contact

NOW

Flow Rate Calculator

System Specific Calculator

| Product | Inside Diameter Inches |

|

|---|---|---|

| RapidAir | 1/2 | .375 |

| MaxLine | 1/2 | .50 |

| MaxLine | 3/4 | .80 |

| MaxLine | 1 | 1.03 |

| MaxLine | 2 | 2.00 |

| FastPipe | 3/4 | .690 |

| FastPipe | 1 | .870 |

| FastPipe | 1-1/2 | 1.430 |

| FastPipe | 2 | 1.810 |

| FastPipe | 3 | 2.990 |

| FastPipe | 4 | 3.67 |

| FastPipe | 6 | 5.57 |

| Tool | |

|---|---|

| Brad Nailer | 1 |

| Blow Gun | 5 |

| Body Polisher | 5 |

| Cut Off Tool | 12 |

| Air Drill | 10 |

| Spray Gun | 10 |

| Impact ½” | 15 |

| DA Sander | 15 |

| Air Ratchet | 5 |

How to determine the diameter for your piping system:

To choose the correct diameter of pipe for your system, you need to know how much flow rate (CFM) will travel through the pipe and how long your piping will be.

When choosing the correct diameter for your piping system, remember that a larger size does increase air flow. A larger diameter will actually drive the cost of the system up. Size your air system for the tools you will use, the compressor horsepower and the size of your building layout.

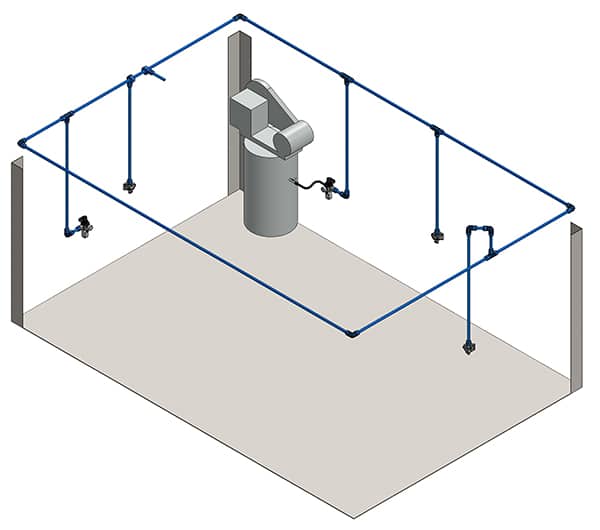

To maximize the flow rate for any of our piping systems, it is best to install your system as a loop. Starting at the air compressor and looping around your shop back to the compressor. This will increase flow rate, decrease pressure drop, and allow smaller line size to be used.

The thread size of the port on your air compressor tank does not determine the pipe size for your piping system. It is calculated with the length of your piping (building size) and air compressor CFM output. Even though the port on your tank may be small, the air is only traveling through a short distance, so the restriction is minimal. Air is only restricted over a long distance with small piping.

Here are some important facts to remember:

- Compressed air gets restricted over long distances

- Flow rate decreases the further it is from the air compressor

- The longer distance the piping runs, the larger diameter of piping you will need

- Larger size piping increases air flow, but also increases the cost of your system

- Sizing down piping at the end of a run decreases flow rate and offers you no benefit

For recommendations on system choices and building sizes, please see our CHOOSE A SYSTEM page.